.

.

.

.

.

Connection secured.

Hi guys, (or gals?) this is an overdue article on our third year project on Energy Conversion and Power Transmission, by our lecturer, who was our also our Electrical Machines lecturer. I figured out that now I have some time to impart the depths of the Vortex Electrica secrets which should be shared. Since our DIY motor project has gained a reputation with our lecturer, he was inspired to tell us to build a generator. The VE bloodline is again revived!! So here we are.

The most satisfying aspect of building a generator is you can see a form of energy that can't be harnessed properly, and it transfers itself into something that can be properly used (like charging a battery from wind flow, an so on). See the video:

Output Demonstration

Why did I post the video first? This is just for you guys who are skeptical at our product. So we'll just impart it all for you to see. This generator generates 30V at around 3500 rpm (revolutions per minute) with no-load (that means the terminals are directly fed to a voltmeter/multimeter. So how are you gonna build it? The concept is too simple since you guys can also see the link regarding our DIY motor: Here

Basic concepts and physics regarding generators can be read from the wiki here:

Concepts on generators

.... and please read 'em properly if you're a complete newbie.

Anyway, here's a simple diagram on our construction (this diagram is property of Vortex Electrica, references must be with citations) :

From the diagram, (study it carefully!!) The construction is pretty simple, and saves a lot of time regarding analysis. The reason we used this design (which is not the best, since industrial generators use more complicated but efficient windings) is to save you from the trouble of winding and re-winding it due to mistakes. Trust me, the biggest problem in construction of this thing comes from winding the coils, which may be up to thousands of repeated windings. You'll not want to unwind 1000 windings after discovering that the generator has problems regarding orientation or discontinuity of the coils. The details regarding winding configuration will be covered in the following sections.

Here comes the important part: Construction.

What are the ingredients we used? Here you are:

1. Broken hard-drives:

We'll need the permanent magnets from these hard-drives, which are NEODYMIUM magnets. These magnets are the strongest magnets ever produced in the industry. A good documentation regarding hard-drive magnets can be seen in this link: Neodymium magnets

A very good tip: You can get them virtually for free or for very cheap prices if you haggle the prices properly in some shops selling computer hardware, where they usually keep scrap hard-drives for scrap metal, but they'd gladly sell them to you for RM2-RM5 apiece.

2. A non-magnetic metal shaft (can be found in CD-drives)

3. Copper coils is pretty easy to obtain cheaply, from broken transformers and so on, but we bought CRT field coils (from old TVs) for RM10 from a shop selling CRTs. You can get yours for free if you have broken TVs in your attic/store. Haha!!

Here's some pictures:

It takes great patience to extricate the coils, which are bonded together with resin, but you'll manage, InsyaAllah.

Now, the basic ingredients are covered. Now, we'll proceed to construction, where the other materials will be described as we go along.

Construction:

A) First Sequence:

Description:

1. Neodymium magnets on brackets

2. Separated magnets, that's how those magnets look like

3. Halved for polarity isolation (see the documentation regarding Neodymium magnets on the link above. In our case, since cutting it in half using non-magnetic blades is not an option, we used a steel hacksaw to make a dent at two positions for weak stress points, then carefully snap 'em in half using your bare hands, they ARE that brittle, so make the dents sparingly)

4. Armature built using the non-magnetic shaft (usually you can get 'em from toys/CD/DVD drives) we held together the magnets with the tubular structure using epoxy glue (A VERY IMPORTANT COMPONENT!!!). The white tubular structures are actually ballpoint pen casings. Very strong and reliable structural material!

5. Materials for the generator frame (we omitted the metal screws for they produce a very large reluctance in the armature movement.)

6. The basic framework completed, note the neodymium magnets' orientation, please use this configuration.

B. Windings:

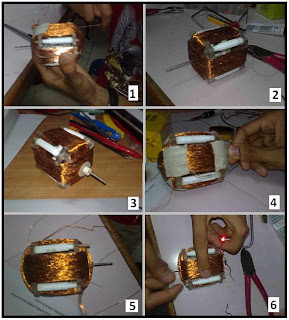

The pictures here are simpler, just to show the coiling progress:

Winding orientation: Two planes of separate winding (Singular winding shown in the figure is for simplification, you'll need to wind as much as you can for both planes SEPARATELY, combined after completing the space provided by the generator framework.)

Winding orientation: Two planes of separate winding (Singular winding shown in the figure is for simplification, you'll need to wind as much as you can for both planes SEPARATELY, combined after completing the space provided by the generator framework.) Description:

Description:1. Coiling like normal: Remember, the coils are separate between the two planes we used to maximize the space usage. Combination between the two planes are done after the winding is completed.

REMEMBER: We coiled one plane, then the other after completing each layer alternatively, this way the coils are uniform (imagine this like doin' hamburgers, you don't make two big layers, you put thin layers of goodies but lots of it alternatively, like bread,meat, salad, dressing, then fried egg, then dressing back, salad, meat and bread in the bottom)

2. Hmmm... are we done? The CRT coils are still abundant.

3. We added an extra nozzle (the white plastic thingy) to increase the winding space and to avoid the coils from colliding with shaft.

4. Covered some of the parts with tape to hold the windings in place, they tend to loosen after a 2 cm layer worth of coils.

5. Looks like an egg ain't it? That's what we called it, "The Golden Egg"... the thing can roll like one too. Hahaha!!

6. VERY IMPORTANT: Make sure you test the output from the coils after completing a number of thin layers. Just directly connect an LED to the terminals, if there is no output you'll just have to unwind a small number of windings rather than unwinding the whole damn thing.

C: Finalization

Description:

1. Covered with electrical tape to rigidify the fuselage

2. A presentable platform, using plastic frames from the CRT and some other scraps, held together using screws and epoxy glue.

3. Testing the output by connecting the generator shaft to a shaft of a DC motor.

4. The outputs are indicated using LCD display (Special division of programming of the PIC by Mr. Fakhruddin (Deathclaw)

Alhamdulillah, the result is extremely satisfying as we've managed to produce the prototype properly and met the objectives with the best output/efficiency (30V DC output for us, other teams got 3V at most, smallest weight/volume and weight/output power ratio also).

Both the outputs are rectified using our own Bridge Rectifiers, each windings got one. Both the rectifiers are connected in series to produce a combined DC output:

All the personnels are involved in the completion of this project:

1. Abdul Halim Poh (Vizier87), Electromechanical Systems

2. Shahrilhafiz (beautifulmind), Power Electronics

3. Fakhruddin (Deathclaw), Programming

4. Nazmi Zulkifli, Team Manager

5. Mr Lew Han Kit, Misc. Assisting Personnel.

There were many mistakes made and we rectified the problems one-by-one, not to mention the pain we experienced due to the wires which tore after the sharp edges of the revolving magnets cut it for being too close, and at one time the magnets flew apart because of the unbelievable velocity of spin, and also two scrapped major designs, each taking a LOT of bloodshed, and for the ones who wish to add an external revolving field similar to this:

.... With the assumption that it will make the output larger with denser magnetic flux, IT'LL NOT WORK, and the output will be even less. This is true for our case and another team's generator. Anyone who can submit the reason, please do so, and your name will be embedded in this article for giving the explanation.

.... With the assumption that it will make the output larger with denser magnetic flux, IT'LL NOT WORK, and the output will be even less. This is true for our case and another team's generator. Anyone who can submit the reason, please do so, and your name will be embedded in this article for giving the explanation.Thanks to everyone involved. May Allah bless us all with the understanding of His creations and ultimately seek refuge under his mercy.

Regards,

Vizier87

Hello

ReplyDeleteI really appreciate you for all the valuable information that you are providing us through your blog.

Electrical Goods Manufacturer

thanks a lot

ReplyDeletei m new on electric u make my interest in electricity/electronics thnx . i will do as u said to make u hero

ReplyDeleteMachaAllah your project is very good. If you want tapping the zpe you ought to use pulses.

ReplyDeleteAbu Bakr TOURÉ from Senegal. Jazak Allah kharaïne.

What amps did this system pump out @ 30V?

ReplyDeleteThanks for sharing! I just got a generator rental for my fiance because we are taking a trip to a cabin in the woods he is building, and I would like to have some power.

ReplyDeleteHi,

ReplyDeleteWe didn't measure the amps, but LEDs got burned at lesser voltages. I suppose that's still low though.

Hi Cecilia,

I heard something about Fisher & Paykel motors selling broken motors, they can be adjusted to make a decent DC generator too.

Thanks for reading!

This seems helpful but how much energy load can it give? Thanks for sharing this information.

ReplyDeleteHi Nadine,

ReplyDeleteIt will be not much, but it'll be a step toward DIY-ing your own electric generator. You'd learn loads from building one.

Cheers.

Nice post dear. New generator sales & bunded fuel tank hire

ReplyDelete